Understanding the Electronics Assembly Process

The electronics assembly process is essential for turning raw components into functional devices that drive technology in everyday life. This guide provides a comprehensive overview, covering fundamental steps, techniques, and emerging trends. Ideal for beginners, engineers, or industry professionals, it explains how to assemble electronic parts efficiently while highlighting quality control and innovation. By exploring topics like the circuit board assembly process and electronic assembler duties, you’ll gain practical knowledge to apply in manufacturing or hobby projects. Expect insights into automation, sustainability, and market growth, all backed by current data.

Defining Electronics Assembly

Electronics assembly involves combining various parts to form complete electronic systems. It’s a meticulous procedure that ensures devices work reliably.

Core Concepts and Significance

At its heart, electronic assembly brings together components such as resistors, capacitors, and microchips on a printed circuit board (PCB). This creates electronic assemblies that power everything from smartphones to medical equipment. The significance is evident in its role in product reliability flawed assembly can cause malfunctions, while precise work enhances performance and longevity.

In the global market, electronics assembly supports a vast industry. The electronics manufacturing services (EMS) market was valued at USD 633.29 billion in 2024 and is projected to grow at a CAGR of 4.8%. Additionally, the worldwide electronics assembly market stands at approximately $1.45 trillion. These figures underscore its economic impact across sectors like consumer goods, automotive, and healthcare.

Evolution Over Time

From manual techniques in the 1950s to today’s automated systems, electronics assembly has advanced significantly. Early methods used through-hole technology, but shifts to surface mount technology (SMT) have enabled smaller, faster productions. This evolution reflects broader technological progress, making devices more compact and efficient.

Essential Steps in Electronics Assembly

The electronics assembly process follows a series of structured phases to achieve high-quality results. Drawing from industry practices, here’s a detailed breakdown.

PCB Design and Fabrication

Everything begins with designing the PCB, which serves as the foundation. Using software like CAD, engineers create layouts, followed by fabrication through processes like etching copper layers. This step is vital in the circuit board assembly process, as errors here can compromise the entire build. Professional fabrication ensures precision, often involving multilayer boards for complex applications.

Sourcing and Preparing Components

Reliable electronic components assembly requires selecting parts from trusted suppliers. This includes checking for quality, compatibility, and certifications. Preparation might involve organizing components or trimming leads. In electrical parts assembly, considerations like supply chain reliability are key to avoiding delays.

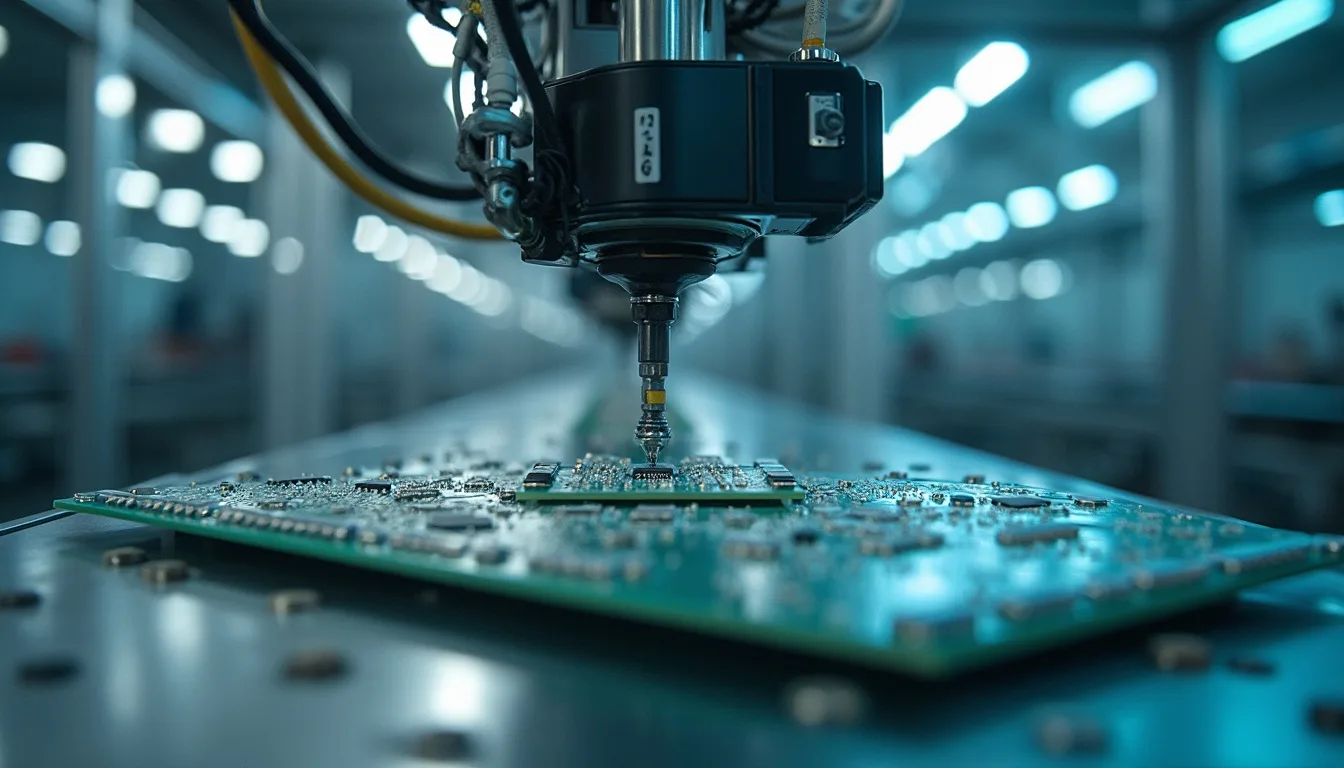

Component Placement and Mounting

Parts are positioned on the PCB using automated pick-and-place machines or manual methods. For high-volume electronic assembly line operations, machines use vacuums to place tiny components accurately. Manual placement suits prototypes, ensuring flexibility in assembling electronic parts.

Soldering Methods

Soldering secures connections. Techniques include reflow soldering, where boards pass through ovens to melt solder paste, or wave soldering for through-hole parts. In electronic board assembly, low-temperature solders are gaining popularity for energy efficiency and reduced thermal stress.

Inspection and Quality Assurance

Post-assembly, inspections detect defects. Automated optical inspection (AOI) scans for misplacements, while X-ray checks hidden joints. Functional testing verifies operation, crucial in the assy process to maintain standards.

Cleaning and Final Integration

Boards are washed to remove residues like flux, using deionized water or ultrasonic methods. Then, integration into enclosures or systems completes the build, including wiring and box assembly.

Packaging for Distribution

Final products are packaged in ESD-safe materials to prevent damage during transit, ensuring they arrive ready for use.

To visualize, here’s a table of core steps:

| Step Number | Phase | Key Activities | Tools Involved |

| 1 | PCB Design | Layout creation | CAD software |

| 2 | Sourcing | Part procurement | Supplier checks |

| 3 | Placement | Component mounting | Pick-and-place machines |

| 4 | Soldering | Connection securing | Reflow ovens |

| 5 | Inspection | Defect detection | AOI, X-ray |

| 6 | Cleaning | Residue removal | Washers |

| 7 | Packaging | Protection | ESD bags |

This structured approach minimizes errors and boosts efficiency.

Varieties of Assembly Techniques

Surface Mount Technology (SMT)

SMT places components directly on the board surface, ideal for compact designs. It’s automated, supporting high-density builds in modern devices.

Through-Hole Technology (THT)

THT inserts leads through board holes, offering strength for rugged applications like electrical assembly.

Hybrid Approaches

Combining SMT and THT provides versatility for complex projects, balancing speed and durability.

Automated Versus Manual Methods

Automation excels in large-scale production, while manual is better for custom circuit assembling. Trends show increasing AI integration for smarter automation.

Responsibilities of an Electronic Assembler

Professionals in this role are key to successful outcomes.

Everyday Tasks

Electronic assembler duties include interpreting schematics, placing parts, soldering, and conducting tests. They ensure compliance with safety standards in production environments.

Necessary Skills

Dexterity, technical knowledge, and problem-solving are essential. Training in tools like soldering irons and multimeters is common.

Career Opportunities

With vocational education, assemblers can progress to supervisory roles. The field offers growth, especially in expanding sectors like renewable energy.

Demand is rising; for instance, roles emphasize precision in high-tech manufacturing.

Current Trends and Market Insights

Emerging Developments

Key trends include additive manufacturing for custom parts, advanced packaging for better performance, and sustainable practices like eco-friendly materials. AI and IoT integration enhance smart factories, while dual-region manufacturing addresses supply chain resilience.

Organic electronics and edge computing are also rising, promoting energy-efficient designs.

Statistical Overview

The EMS market is set to grow by USD 188 billion from 2025-2029. Semiconductor assembly equipment market is at USD 9.85 billion in 2025, expected to reach USD 20.96 billion. These stats reflect robust expansion driven by demand for advanced tech.

Future Projections

Anticipate more focus on sustainability and automation, reducing environmental impact while improving efficiency. Innovations like low-temperature soldering will minimize energy use.

Advantages of Outsourcing Electronics Assembly

Partnering with specialists offers clear benefits.

Efficiency in Costs and Scaling

Outsourcing cuts in-house expenses, allowing easy scaling from prototypes to mass production.

Enhanced Quality

Providers use advanced testing, ensuring reliable outcomes and fewer defects.

Accelerated Production

Expert services speed up timelines, with some offering turnarounds in days, versus industry weeks.

- Expert Access: Leverage specialized skills without training costs.

- Regulatory Compliance: Meet standards like ISO seamlessly.

- Innovation Boost: Incorporate cutting-edge methods effortlessly.